Description

Automatic viscous liquid sauce filling machine gel bottle filling machine

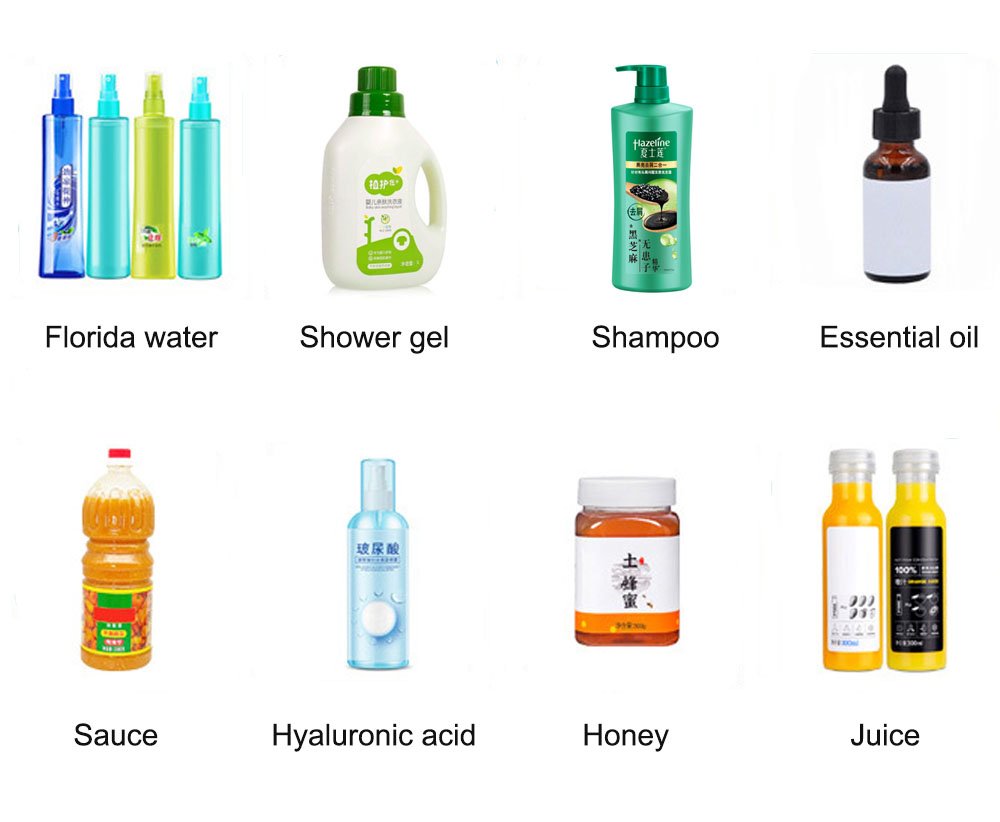

Application of viscous liquid sauce filling machine

Sauce filling machine is suitable for filling various liquids/creams in food, medicine, cosmetics, chemical industry, and other industries. Rotor pumps are ideal for filling a wide range of liquids and viscous fluid products, especially those with high viscosity or containing particles.

Features of liquid bottle filling machine

1. High-precision filling, using rotor pump metering, can accurately control the filling volume, suitable for products with high viscosity, particles or solid materials, such as pastes, sauces, honey, etc.

2. It has a wide range of applications and can handle liquids of different viscosities, including low viscosity to high viscosity fluids, especially suitable for food, chemical, pharmaceutical, daily chemical and other industries.

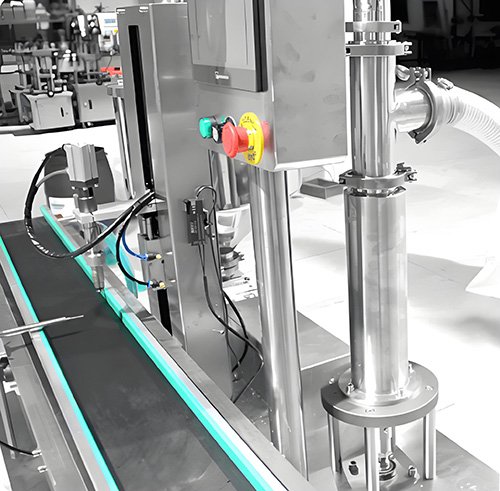

3. User-friendly operation interface: PLC control. Parameters can be set up on the touch screen. Easy to operate.

4. The equipment adopts a compact design, occupies a small area, and is suitable for various production environments.

5. Made of food-grade stainless steel 304, in compliance with GMP and food hygiene standards, easy to disassemble and clean.

6. The machine can be fitted with an automatic feeding function to achieve fully automated production. It can also be connected with other production lines or equipment to form a complete production line and improve production efficiency.

Parameters of servo bottle filler machine

Power supply | 220V |

Power | 1KW |

Machine frame | SUS304 |

Hopper volume | 40L |

Production capacity | 1800-3000bottles/hour |

Filling volume | 5-5000ml |

Bottle mouth diameter | 10-100mm(can be customized) |

Bottle Height | 10-300mm(can be customized) |

Machine weight | 200kg |

Air pressure | 0.5-0.8mpa |

Machine size | 2000*900*1650mm |

Machine details:

SUS304 machine body

Food grade 304 stainless steel material, high temperature resistance, corrosion resistance.

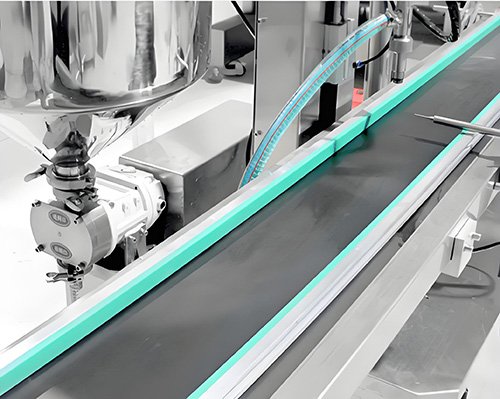

Auto loader

Automatic feeding, saves labor and effort, sustainable operation.

Rotor pump

Rotor pump driven filling, high viscosity pump, high-speed conveying of thin materials, durable, no wearing parts, no friction, using rotor pump control to make the filling accuracy more accurate, more convenient to adjust the filling volume, and easy to clean.

Fiber optic photoelectric sensor

Accurate positioning, no bottle, no filling.

About our company:

Guangzhou Borui Intelligent Equipment Co., Ltd. was founded in 2016. It is a packaging machinery manufacturing enterprise integrating R&D, design, manufacturing, sales, and service.

Our products mainly include Tube filling sealing machines, Liquid cream filling and capping machines, vertical form fill seal machines(VFFS packaging machines), Flow packaging machines, Caps screwing machines, Automatic packing lines, Cling film wrapping machines and other series of mechanical equipment. Products are widely used in food, agriculture, medicine, chemical, daily necessities, hardware, and other industries. The products have high technical content, strong practicability, and a good reputation. They are sold well all over the country and exported to Asia, the Middle East, Europe, America, and other countries and regions.