Description

Automatic plastic cosmetic tube ultrasonic tube filling and sealing machine

Application of Automatic tube filler sealer machine

It is suitable for filling and sealing various plastic tubes or aluminum plastic tubes in food, medicine, cosmetics, chemical industry, and other industries.

Features of cosmetic tube filling sealing machine

1. Utilizing digital ultrasonic system for sealing (Automatic frequency tracking, no need human adjusting), ensuring perfect and stable sealing effects. The welding strength is equivalent to that of the plastic itself, with a good sealing effect, strong seal, clear pattern, no deformation, and no bursting.

2. The machinery is fully automated, efficiently handling the entire process of tube feeding, sorting, positioning, filling, ultrasonic sealing, coding, trimming, and discharging the finished product.

3. Capable of sealing a wide range of plastic tube materials including PE, PP, PVC, laminated tubes, etc.

4. Equipped with PLC control, parameters can be set up on the touch screen, saving time and costs.

5. With tube orientation system to guarantee consistency and perfection in sealing.

6. Includes date coding functionality to enhance product traceability and quality control.

7. Different sizes of tubes can be sealed. Only need to change the tube holder when tubes of different diameters need to be sealed.

8. Space-saving design makes it suitable for use in various manufacturing environments, maximizing floor space utilization.

9. Ultrasonic sealing machines typically have low maintenance requirements, with durable components and convenient maintenance.

10. This machine is made of 304 stainless steel, resistant to acid, alkali, and corrosion. The entire machine meets GMP standards.

Parameters of automatic cosmetic tube filling sealing machine

Voltage | 220V, 50/60Hz |

Frequency | 20KHZ |

Power | 2600W |

Air pressure | 0.6Mpa |

Tube length | 70-200mm |

Tube diameter | 16-50mm |

Sealing speed | 20-25pcs/min |

Filling accuracy | ±1% |

Filling range | 6-60ml/10-120ml/25-250ml |

Machine size | 1630*1380*1720mm |

Machine weight | 450kg |

Machine body | SUS304 |

Machine details:

Color mark detector

The color mark detector is used to detect the color mark of the plastic tube and rotate it to the correct position, and ensure the consistency and perfection in sealing.

Filling nozzle

High filling accuracy, with anti-drip design. It is suitable for filling liquid/cream.

Date coding function

With date coding function to enhance product traceability and quality control.

Rotate working station

With 10 working stations, improve working efficiency.

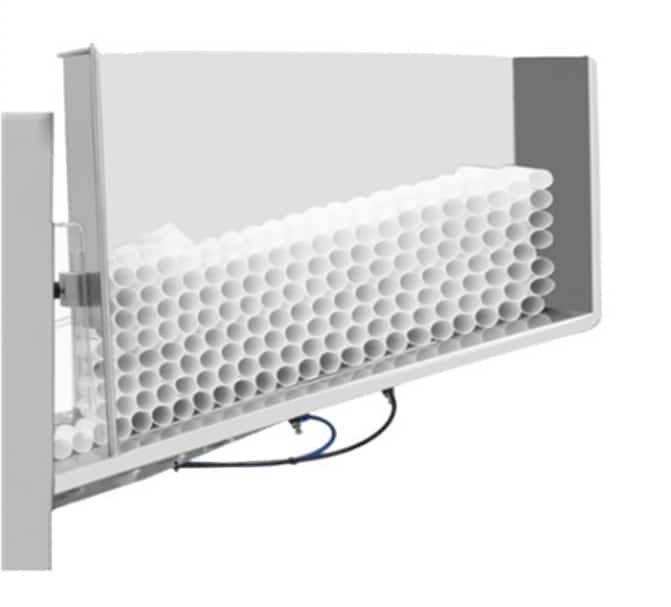

Tube container

With stainless steel tube container. It can hold 200-400tubes.

Our company:

Guangzhou Borui Intelligent Equipment Co., Ltd. was founded in 2016. It is a packaging machinery manufacturing enterprise integrating R&D, design, manufacturing, sales, and service.

Our products mainly include Tube filling sealing machines, Liquid cream filling and capping machines, vertical form fill seal machines(VFFS packaging machines), Flow packaging machines, Caps screwing machines, Automatic packing lines, Cling film wrapping machines and other series of mechanical equipment. Products are widely used in food, agriculture, medicine, chemical, daily necessities, hardware, and other industries. The products have high technical content, strong practicability, and a good reputation. They are sold well all over the country and exported to Asia, the Middle East, Europe, America, and other countries and regions.